Last Tuesday, February 18, 2025, the FactorIA Project “Research and Development of AI technologies to provide maximum autonomy to the manufacturing and repair of large, high-value parts using DED processes” was launched in Derio at the facilities of the TECNALIA RESEARCH & INNOVATION Research Organization located in the Bizkaia Science and Technology Park.

Project file number MIG-20242026 is funded by the CDTI (Spanish Institute of Technology and Innovation) through the 2024 Call for Proposals for the “SCIENCE AND INNOVATION MISSIONS – TRANSMISSIONS” Program, within the framework of the Transfer and Collaboration Program of the State Plan for Scientific and Technical Research and Innovation; it has also been supported by the Ministry of Science and Innovation. The TransMisiones 2024 initiative is a collaborative effort between the CDTI (Spanish Institute of Technology and Innovation) and the AEI (Spanish Institute of Technology and Innovation), included in the PEICTI (Spanish Institute of Technology and Innovation). This initiative coordinates funding for groups of research and knowledge dissemination organizations and business groups that collaborate to jointly develop coordinated R&D activities that address the challenges identified in the thematic priorities (Misiones). On behalf of the AEI Group, the consortium includes three universities (UNIVERSITY OF THE BASQUE COUNTRY, UNIVERSITY OF NAVARRE, PUBLIC UNIVERSITY OF NAVARRE) and one public research center (INSTITUTE OF PHYSICAL AND INFORMATION TECHNOLOGIES “LEONARDO TORRES QUEVEDO” (ITEFI), an institute of the Spanish National Research Council (CSIC). All of them complement each other in the development of their activities to address the challenges posed by FactorIA.

The FactorIA project has a total budget of €6,867,956 million from the CDTI group and will last four years, concluding at the end of 2028.

FactorIA is led by TECSA, with the participation of ASTILLEROS MURUETA, DGH ROBOTICS, IBARMIA, LEBARIO, INNESPERC, KEYLAND, and SOTHIS, and with technical support from the TECNALIA RESEARCH & INNOVATION research organization.

TECSA specializes primarily in providing maintenance services to railway networks in Spain, being the company that has built and maintains the largest number of kilometers of the high-speed network. ASTILLEROS MURUETA is a shipbuilder with the experience of more than 200 vessels built based on studied hydrodynamics, materials, and advanced electronics, etc. DGH Group is a company specialized in industrial engineering and maintenance, recognized as one of the ten best robotics suppliers in Europe. IBARMIA specializes in machining centers, pioneering the adoption of additive manufacturing technologies using lasers, and developing the concept of machine tool fingerprinting to optimize maintenance. LEBARIO specializes in the manufacture of molds for high-pressure die casting (HPDC). INNERSPEC is a medium-sized company specializing in NDT (Non-Destructive Testing), designing a complete system for the inspection of space shuttle booster rockets, and is a service provider for companies in the aeronautical and aerospace sectors such as NASA, SPACEX, and AIRBUS. KEYLAND is a technology company specializing in digitalization and automation for Industry 4.0 with proprietary technology. SOTHIS specializes in integrated information technology solutions, business and industrial management, implementing cybersecurity, data analytics, and artificial intelligence techniques.

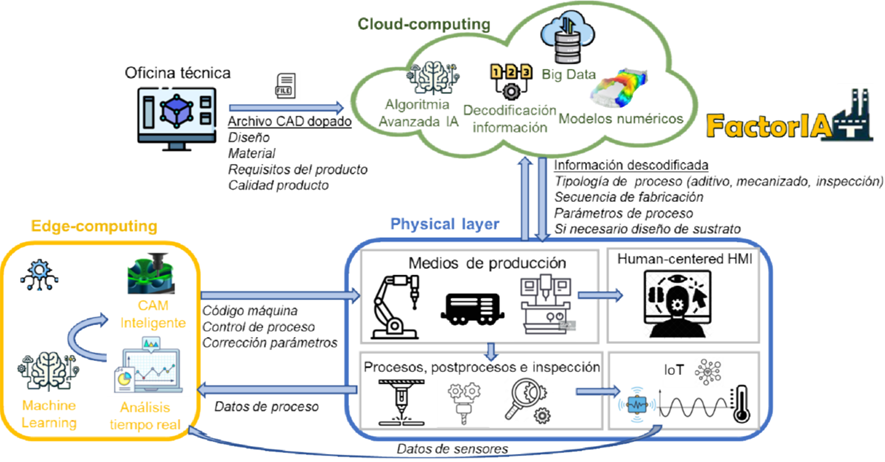

The objective of the FactorIA project is to transform the current manufacturing flow from Technical Office to Operator to Production Means to the Technical Office to Production Means to Operator flow. In this new paradigm, production resources evolve at a conscious level, guiding operators through operations that require their intervention.

The FactorIA project is aligned with the mission of “Promoting secure IoT and edge computing, as well as related deep cross-cutting technologies, to advance toward the autonomous factory.” It aims to research a wide range of technologies that will contribute to the development of the autonomous factory (lights-out), adding value and innovation by utilizing state-of-the-art research techniques in various technologies, including: artificial intelligence, IoT, deep learning, digital twins, robotics, cybersecurity, cloud and edge computing, metal additive manufacturing (MAM) using directed energy deposition (DED) in its laser-DED and arc-DED versions, and others, improving them to adapt them to the future industrial context. Among these enabling technologies, the FactorIA project will investigate industrial software platforms, advanced AI algorithms, machine and deep learning, cloud and edge computing, wireless sensors, and enhanced communications and networks, all integrated under the concept of DIGITAL THREAD to enable autonomy in manufacturing, joining, and repair through Metal Additive Manufacturing (FAM) DED (Directed Energy Deposition), inspection, and post-processes such as advanced machining 4.0 of large, high-value parts.

FactorIA’s developments will exponentially increase the intelligent automation and digitalization of processes such as welding and FAM/DED in Spanish companies. The project’s research, development, and results will be applicable to other processes that present similar challenges.

FactorIA will help respond to Spain’s 2050 challenges of “Being more productive to grow better” and “Becoming a carbon-neutral, sustainable, and climate-resilient society.”

Ultimately, the systems and processes developed and optimized at FactorIA will combine advanced automation tools with other technologies, such as the Internet of Things (IoT), Edge Computing, Machine Learning, Advanced Algorithms for autonomous decision-making systems, Cloud Computing, predictive functionalities, Cybersecurity, as well as other 4.0 technologies such as Computer Vision, Metal Additive Manufacturing, DED, Machining 4.0, hybrid physical-digital models (digital twins), advanced control systems, continuous process monitoring systems, NDT inspection technologies, etc., encompassing them all under an integrative Digital Thread.

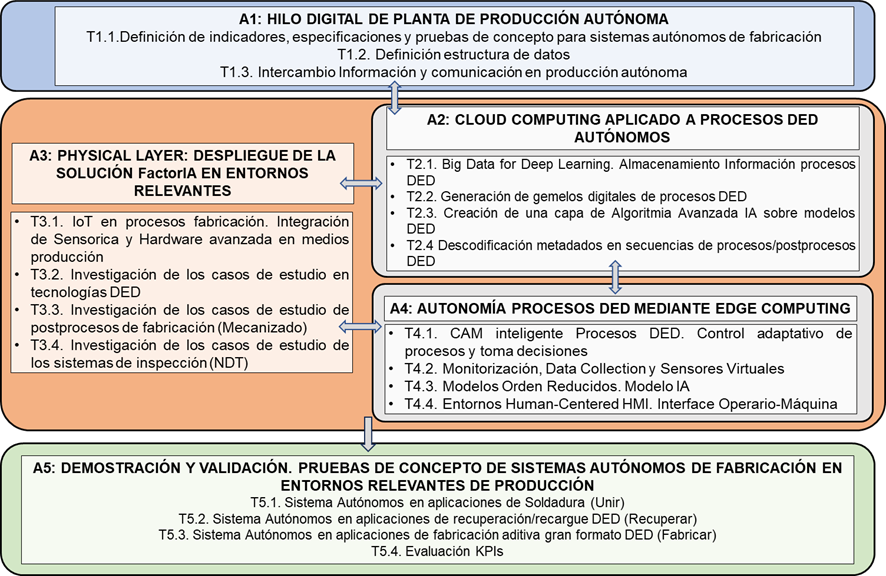

To achieve these goals and objectives, FactorIA proposes five action activities: